Providers of National Disability Insurance Scheme (NDIS) services must ensure that a risk management system is in place to protect NDIS participants, workers, the general public, and the organisation itself from harm.

What is Risk Management?

Risk management is the process of identifying, assessing and controlling risks. It should be a proactive, planned, and systematic process that addresses all potential hazards and risks in the workplace. Risk assessment is not a one-off task; it should be an ongoing process that responds to changes in the workplace and allows for continuous improvement. It should also be performed before undertaking any hazardous work activities (Safe Work Australia 2018).

Under the NDIS, a risk management system should comprise:

- Incident management

- Complaints management

- Work health and safety

- Human resource management

- Financial management

- Information management

- Governance.

(NDIS 2021)

Benefits of Risk Management

Effective risk management can help to:

- Protect the safety and wellbeing of participants, workers, and the general public

- Reduce the risk of adverse events, or harm from adverse events

- Optimise the results of positive events

- Ensure efficient and effective services

- Ensure facilities and equipment are managed and maintained

- Enhance confidence in the provider’s services

- Ensure the provider operates within its allocated budget

- Reduce the risk of legal action being taken against the provider

- Ensure the provider follows legislative or funding requirements

- Ensure that the risk management strategies implemented are cost-effective.

(Real Living Options 2018; NDS 2016)

Risk Management in the NDIS Practice Standards

Risk management is a requirement of the NDIS Practice Standards under Core Module 2: Provider Governance and Operational Management.

This Practice Standard aims to ensure that any risks to NDIS participants, workers, and the provider are identified and managed (NDIS 2021).

NDIS providers must meet the following quality indicators:

- Any risks are identified, analysed, prioritised and treated. These risks may include:

- Risks to NDIS participants

- Risks to workers

- Risks to business operations

- Risks to service provision

- Providers have a documented system for managing risks effectively. This risk management system should be relevant and proportional to the provider's size and scale, as well as the scope and complexity of the services being delivered.

- The delivery of supports should be linked to a risk management system.

(NDIS 2021; WAAMH 2021)

The Risk Management Process

There are four steps in the risk management process:

- Identify hazards

- Assess risks

- Control risks

- Review control measures.

(Safe Work Australia 2018)

Risk management should be conducted together with the participant, and any control measures should be implemented as part of their care or service plan (Queensland Government 2018).

1. Identify Hazards

Hazards are any objects or situations that have the potential to cause harm. Some hazards may be an inevitable part of your work, but others may be the result of accidents or failures (Safe Work Australia 2018).

There are a variety of hazards involved in the delivery of NDIS supports that may affect participants, staff, providers, or the general public, including (but not limited to):

- Manual handling

- Work-related stress

- Occupational violence

- Slips, trips, and falls

- Bullying and harassment

- Physical hazards

- Participant dissatisfaction

- Loss of government funding or changes to funding

- Equipment (e.g., wheelchairs or lifting hoists)

- Inadequate allocation of human, physical, financial, or other resources

- Financial hazards/mismanagement

- Fraud

- Failure to comply with legislation

- Confidentiality breaches

- Service disruption or closure

- Lack of staff

- System or technology failures

- Difficulty retaining staff.

(WorkSafe Victoria 2022; Real Living Options 2018; Sykes 2024)

2. Assess Risks

Once a hazard has been identified, the next step is to conduct a risk assessment. This will help you to determine the overall severity of the risk, whether existing control measures are effective, whether you need to take any further action, and how urgently further actions should be taken (Safe Work Australia 2018).

Note: If the particular risk is already well-known, with established control measures, a formal risk assessment may not be necessary (Safe Work Australia 2018).

Ask the following three questions:

1. How severe would the potential harm be?

- What harm could occur as a result of the hazard? (e.g., injury, illness, death)

- Are there any other factors that could influence the severity of potential harm? (e.g., the distance of a fall)

- How many people could be harmed?

- Are there any situations that could increase the severity of an accident?

2. How could harm occur?

- What sequence of events could lead to harm occurring?

- Can one or more of the events in the sequence be stopped or changed?

3. What is the likelihood of harm occurring?

- Is it certain, very likely, likely, unlikely, or rare?

- How often does the hazard have the potential to cause harm?

- How effective are current control measures (if any) in reducing the risk?

- Could differences in operating conditions increase the risk?

- Does the working environment increase the risk?

- If harm occurs, how long would people be exposed to it?

- Could the likelihood be affected by the way people act or behave?

- Does the likelihood depend on the people involved?

(WorkSafe Victoria 2017)

3. Control Risks

The next step is to determine appropriate control measures for addressing the risk. Generally, the best way to control risk is to eliminate it as much as reasonably practicable. However, this is not always possible, as certain risks are inevitable (WorkSafe Victoria 2017).

For example, the risk of passing infectious diseases on to a participant cannot be completely eliminated, as being physically present is an essential component of the service you are providing.

In these cases, the next best option is to minimise the risk as much as reasonably practicable (WorkSafe Victoria 2017).

The process of determining appropriate control measures involves the following:

- Identifying the appropriate options for control measures

- Deciding the option(s) most suitable for eliminating or reducing the risk effectively

- Implementing the chosen control measure(s).

(WorkSafe Victoria 2017)

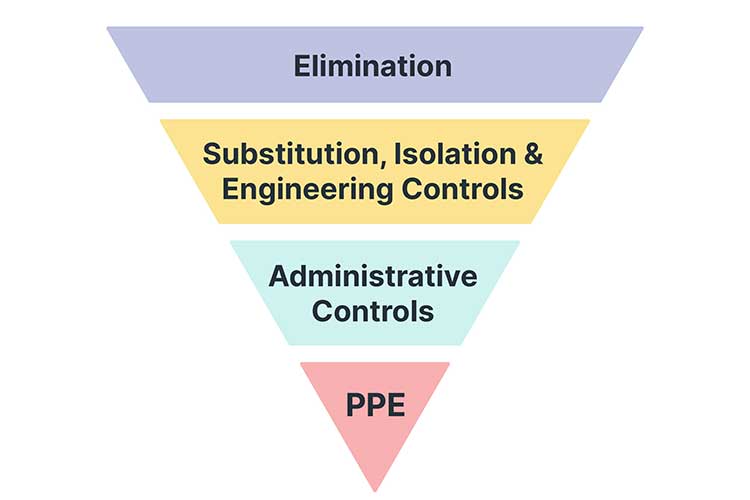

The Hierarchy of Control Measures

The hierarchy of control measures lists different types of control measures from most to least reliable. You should always aim for elimination, as it offers the highest level of protection and is most effective in reducing the risk of harm. However, if elimination is not feasible, you should work your way down the hierarchy until you find the next best option (Safe Work Australia 2018).

Keep in mind that the lower levels of the hierarchy are less effective because, without eliminating the hazard, there is no way to completely remove the risk. Even if you are able to minimise the risk, it will still exist in some capacity (Safe Work Australia 2018).

As a general rule:

- Eliminating the risk is the most effective

- Changing the risk to minimise it is less effective

- Changing how people behave and expose themselves to the risk is the least effective.

(WorkSafe Victoria 2017)

Elimination

Elimination involves completely removing the hazard and its associated risks.

This can be achieved through:

- Not introducing the hazard in the first place

- Removing the hazard (e.g. disposing of a hazardous object, refraining from going to a hazardous place).

(Safe Work Australia 2018)

Substitution, Isolation or Engineering Controls

The next best option is to either:

- Substitute the hazard with a safer alternative

- Physically isolate the hazard from people

- Implement an engineering control (mechanical device or process) to reduce the risk (e.g., a trolley to move heavy objects).

(Safe Work Australia 2018)

Administrative Controls

Administrative controls are work methods or procedures that aim to minimise exposure to the hazard and provide appropriate information, training, and instruction to staff. Examples include implementing new policies or using signs to warn people about a hazard (Safe Work Australia 2018).

Personal Protective Equipment (PPE)

PPE should be used to reduce any remaining risks. It must be used and worn correctly in order to be effective (Safe Work Australia 2018).

4. Review Control Measures

The final stage of the risk management process is to regularly check that control measures are working effectively. Control measures should be reviewed:

- When they are not working effectively

- Before changes that may cause new or different risks to arise

- When new hazards or risks emerge

- When a review is indicated or requested.

(Safe Work Australia 2018)

The Risk Management Process in Practice

Scenario: Shelly is an NDIS support worker for Tim, who uses a walking frame. When Shelley arrives at Tim’s home this morning, she realises that one of the wheels on Tim’s walking frame isn’t working properly.

1. Identify Hazard

In this case, the hazard is the dysfunctional wheel on Tim’s walking frame.

2. Assess Risk

In order to assess the risk, Shelley now needs to ask the following questions:

| How severe would the potential harm be? |

|

| How could harm occur? |

|

| What is the likelihood of harm occurring? |

|

3. Control risk

Using the hierarchy of control, Shelley should now determine her options for controlling this risk.

| Elimination |

|

| Substitution / Isolation / Engineering controls |

|

| Administrative Controls |

|

| PPE |

|

4. Review Control Measures

The safest option until a new frame arrives is to remove the broken frame, report the issue, and use other safe manual handling equipment. During this process, Shelley should check in with Tim to ensure he is still able to appropriately meet his daily needs. If not, this should be addressed.

Test Your Knowledge

Question 1 of 2

You are an NDIS worker who provides support to a participant, Frank, in his home. You notice that Frank often leaves his shoes at the front entrance, which could cause someone to slip. What would be the best and most appropriate control measure for managing this hazard?

Topics

References

- National Disability Services 2016, Risk Management, NDS, viewed 14 August 2024, https://www.nds.org.au/resources/risk-management

- NDIS Quality and Safeguards Commission 2021, NDIS Practice Standards: NDIS Practice Standards and Quality Indicators, Australian Government, viewed 14 August 2024, https://www.ndiscommission.gov.au/sites/default/files/2022-02/ndis-practice-standards-and-quality-indicatorsfinal1_1.pdf

- Queensland Government 2018, A Guide to Working Safely in People’s Homes, Queensland Government, viewed 14 August 2024, https://www.worksafe.qld.gov.au/__data/assets/pdf_file/0012/22233/community-working-safely-in-peoples-homes.pdf

- Real Living Options 2018, Risk Management, Real Living Options, viewed 14 August 2024, https://www.reallivingoptions.com.au/wp-content/uploads/2018/02/NDIS-GOV-14-Risk-Management.pdf

- Safe Work Australia 2018, Model Code of Practice: How to Manage Work Health and Safety Risks, Australian Government, viewed 14 August 2024, https://www.safeworkaustralia.gov.au/system/files/documents/1901/code_of_practice_-_how_to_manage_work_health_and_safety_risks_1.pdf

- Sykes, A 2024, The NDIS Risk Factor, RSM Australia, viewed 14 August 2024, https://www.rsm.global/australia/insights/industry-insights/ndis-risk-factor

- Western Australian Association for Mental Health 2021, Readiness Workbook: NDIS Practice Standards & Quality Indicators, WAAMH, viewed 14 August 2024, https://waamh.org.au/assets/documents/sector-development/ndis-qsc-sector-readiness/waamh-ndis-readiness-workbook-interactive-final-1-.pdf

- WorkSafe Victoria 2017, Controlling OHS Hazards and Risks, Victoria State Government, viewed 14 August 2024, https://content.api.worksafe.vic.gov.au/sites/default/files/2018-06/ISBN-Controlling-OHS-hazards-and-risks-handbook-2017-06.pdf

- WorkSafe Victoria 2022, Disability Services: Safety Basics, Victoria State Government, viewed 14 August 2024, https://www.worksafe.vic.gov.au/disability-services-safety-basics

New

New